Mezzanines by Design provides turn-key services for all types of elevated structures. We work collaboratively with your team from concept design through project fruition. The MBD process includes design, approval documents, comprehensive engineering analysis, PE-stamped documents, shop drawing production, fabrication, coatings, delivery and installation. Our in-house design and fabrication capability stream lines our work-flow and results in excellent project lead-times.

Services

Our design, engineering, and quality control processes are devised to move projects to fabrication as quickly and efficiently as possible. Client collaboration begins at the quote stage, and our engineers are available to discuss project requirements or answer questions at any time.

All platform designs meet the Codes and Standards applicable to the specific structure type, usage, and geographic location. PE-stamped drawings and calculations are provided at the completion of the design phase and are stamped by an Engineer licensed in the State that the platform will be located.

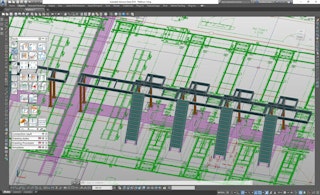

Mezzanines by Design uses Autodesk Advance Steel to model and document all our structures. Advance Steel is built on the industry-standard AutoCAD software but adds many tools to aid in efficiently modeling entire structures with connections, railing, stairs, etc. included directly in the model. Our Advance Steel models can be exported to several different formats for the client’s review of their structure. Advance Steel can also import external models to allow for greater collaboration during the design process. This ability to share models is necessary for BIM and greatly increases our ability to design, fabricate, and deliver our structures quickly and accurately. All drawings are directly linked to the model to ensure every drawing captures all the changes throughout the design and collaboration process. Advance Steel creates Approval Drawings for client review as well as detailed fabrication drawings used by our shop to fabricate each piece of the structure.

- Engineering capabilities include the following:

- Design for high seismic activity zones, high environmental loads, dynamic structural loading, equipment deflection limits or other operational constraints

- Finite Element Analysis

- Fatigue Analysis

- Vibration Analysis

- Existing Foundation Analysis and Footing and Pier Design

Modular design to allow partial preassembly prior to shipping and/or for client inspection

Mezzanines By Design utilizes our own, in-house, fabrication shop to ensure all fabricated items meet our strict quality standards. As an AISC certified fabricator for over 13 years, we inspect every part during and after each process is performed to ensure the highest quality product. 100% of our welds are visually inspected at a minimum with additional weld inspections as required (Magnetic Particle, X-ray, Ultrasound, etc.). Our experienced team of fitters, welders, and machine operators use state-of-the-art software to aid in fabricating components for our platform structures (equipment platforms, catwalks, cross-overs, mezzanines, etc.). Our capabilities include:

- Cutting

- Fitting

- Welding

- Bent Plate

- Bent Pipe

- CNC Beam Drill Line

- CNC Plasma Table

- Sand Blasting

- Powder Coating

Hot-Dipped Galvanized

Mezzanines by design provides full installation services in all 50 states. Our install team arrives at the job site with all of the gear, tools, and equipment needed to safely off-load, stage and erect your structure. Since our platform designs are entirely nut-and-bolt construction, no on-site hot work is required to install the platform. The completed mezzanine and job site area are left fully cleaned and ready for immediate use.

Our installers have completed the following training:

- OSHA 30-hour Construction Safety and Health (supervisor)

- OSHA 10-hour Construction Safety and Health (crew members)

- Scissor lift and Forklift Operation Certifications

- Overhead Crane Operator Certification

Additional special provisions offered:

- Working off-shift hours and on weekends to accommodate operating production schedules and minimize down time.

- Formal documentation such as job hazard analysis, rigging plans and platform installation plans

- Completion of customer required site-specific orientation and safety training

- Pre-assembly of platform structural modules prior to shipping to compress installation time and/or for customer inspection at our shop facility

- Rigging crews as needed for extra-tall and multi-level platforms and for installation sites where access is limited by existing equipment and machinery in the platform erection area

Site checks to evaluate materials routing, staging areas, and site constraints and to assess and mitigate potential problems